A Comprehensive Guide To Imprint Methods: Everything You Need To Know

Discover the ultimate guide to different imprint methods for promotional products. Learn everything you need to know about imprinting your logo

Promotional products play a crucial role in marketing strategies, and imprint methods are essential for adding designs or logos to these items. With numerous techniques available, it can be overwhelming to choose the right imprint method for your specific needs.

This comprehensive guide aims to provide you with everything you need to know about different imprint methods. We will explore various techniques for adding artwork onto the item such as screen printing, pad printing, debossing, engraving, embroidery, and more. By understanding the advantages and disadvantages of each method, you can make an informed decision based on factors like color options, durability, color process, and cost.

Additionally, we will discuss commonly used techniques and emerging trends in this field. Whether you are a business owner or a marketing professional looking to enhance your promotional products’ impact, this article will serve as a valuable resource to help you select the most suitable imprint method for your needs.

Types of Imprint Methods

Types of imprint methods, such as screen print, pad printing, debossing, engraving, embroidery, heat transfer, embossing and debossing, digital printing, full-color imprint, sublimation, foil printing, laser etching, offset printing, allow for a wide range of options and unique way to add logos or designs onto promotional products. These imprint methods offer businesses the opportunity to customize their promotional items using these popular printing with their brand logo or design in order to increase brand recognition and create a lasting impression on potential customers.

Screen print is one of the most commonly used imprint methods. It involves applying ink through a screen onto the product. This method is suitable for large designs and can be done on various materials such as apparel, pens, and bags.

Pad printing is another popular technique that uses a silicone pad to transfer ink from an engraved plate directly onto the product. It is often used for small or irregularly shaped items.

Debossing creates a depressed design by pressing it into the material using a heat press and pressure. This method adds an elegant and sophisticated touch to products such as leather goods or stationery items.

Embroidery involves stitching thread directly onto fabric products to create intricate designs. It is commonly used on clothing items like hats or jackets and works best with fabric.

There are numerous imprint methods available for businesses to choose from when customizing promotional products. Each method offers its own unique advantages depending on the item, and factors such as design complexity and material type. By utilizing these imprint methods effectively, businesses can enhance their brand image and leave a lasting impression on recipients of their custom promotional products.

Advantages and Disadvantages

Advantages and disadvantages of various imprint methods are important to consider in order to make an informed decision when selecting the most suitable method for a promotional item. When it comes to imprint methods, there are several options available, each with its own set of advantages and disadvantages.

- Screen printing: (Ink through the screen) This method is most commonly used that allows for vibrant and long-lasting prints. It is cost-effective for large quantities like t-shirts and tote bags but may not be suitable for complex designs or small details.

- Embroidery: This method provides a professional and high-quality finish, especially on apparel items. It offers durability and can withstand repeated washings. However, it may not be suitable for intricate designs or small text.

:max_bytes(150000):strip_icc()/close-up-picture-workspace-of--embroidery-machine-843488278-9128a2c096844857ba45780ac755fdba.jpg)

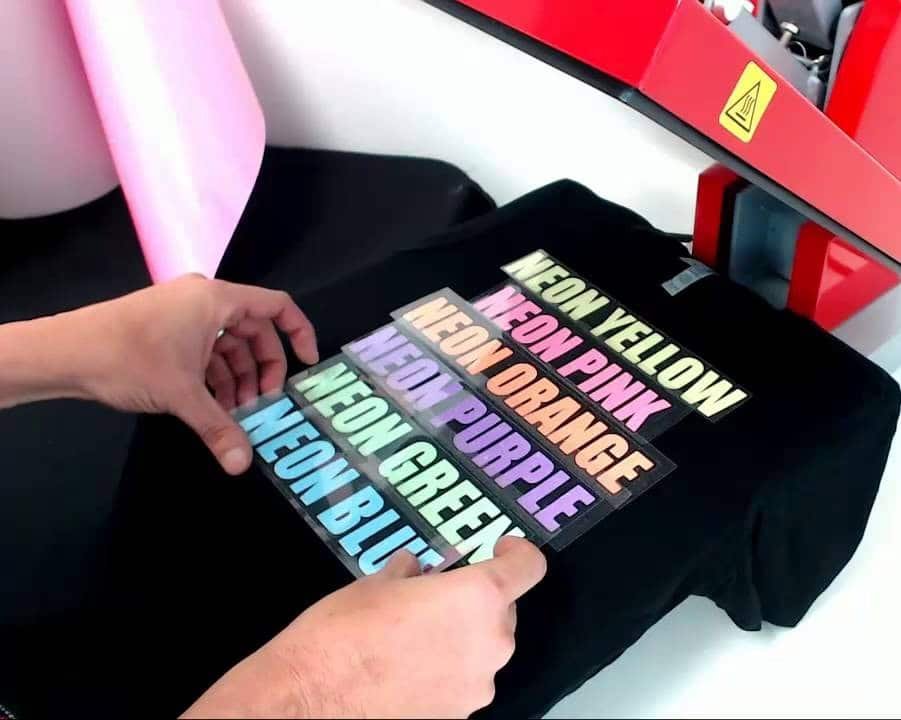

- Heat transfer: This method allows for full-color prints with vibrant colors. It is versatile and can be used on various materials such as fabric, ceramic, and metal. However, it may not be as durable as other methods and can peel or crack over time.

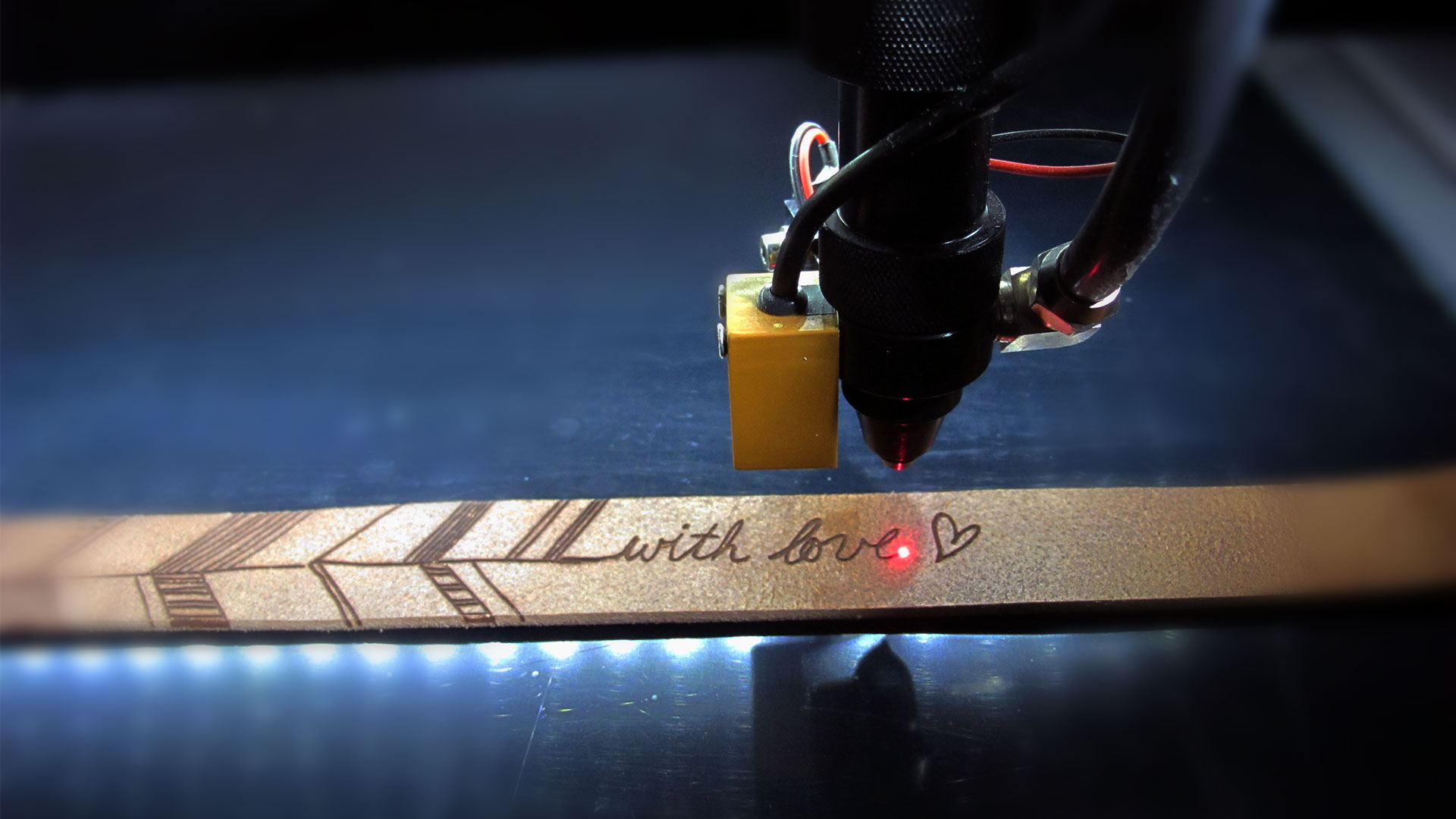

- Laser Engraved: Laser engraving uses and offers exceptional precision, allowing for intricate designs and fine details, usually for hard surfaces material from the product. The laser engraving method creates a permanent imprint that is resistant to fading, wear, and moisture application for a long-lasting output. Some materials may not be suitable for this printing technique due to their composition or reflective properties.

- Four Color Process: Allows a wide range of colors and accurate color reproduction with multi-color. This printing method is used and ideal for reproducing complex and detailed images, including photographs and gradients. However, using a full color process with extremely fine details or text may not reproduce as sharply as with other printing methods.

When choosing an imprint method, it is essential to consider a wide variety of product factors such as the type of product being imprinted, the desired appearance of the design, budget constraints, and turnaround time.

By considering these advantages and disadvantages, one can select the most appropriate imprint method that meets their specific needs.

This comprehensive guide provides everything you need to know about imprint methods to help make an informed decision when selecting the best option for your promotional product.

Choosing the Right Method

When considering the most suitable imprint method, it is essential to evaluate factors such as the product’s material, design complexity, and desired durability, especially for custom design. Each imprint method has its advantages and disadvantages, making it crucial to choose wisely.

Engraving is a popular imprint method that involves etching designs onto a surface using various techniques such as laser beams or mechanical tools resulting in a long-lasting and flawless appearance. It offers a permanent and high-quality result that can withstand wear and tear. However, engraving may not be suitable for intricate designs or certain materials.

Embossing is another commonly used method where the design is raised above the surface of the product. This adds an elegant and tactile element to the item but may not work well with complex logos or fine details.

Digital printing is a versatile option for full-color designs on various materials. It utilizes advanced technology to transfer ink onto the product directly from a digital file. This method is ideal for detailed artwork but may not provide long-lasting results on certain surfaces.

Silk screen printing involves pushing ink through a mesh screen onto the product’s surface. It allows for vibrant colors and precise details, making it suitable for large quantities of products. However, this method may have limitations when it comes to complex designs or small text.

Dye sublimation uses heat to transfer dye onto polyester fabrics or specially coated items. It provides vibrant colors and allows for full-color printing without fading over time. However, this method may not be compatible with all materials.

Selecting the right imprint method requires careful consideration of factors such as material compatibility, design complexity, and desired durability. By understanding these factors and evaluating each option’s advantages and disadvantages like engraving, embossing, digital printing, silk screen printing, and dye sublimation one can make an informed decision that meets their specific needs in terms of aesthetics and functionality.

Commonly Used Techniques

A variety of imprint techniques are widely employed in the industry to achieve visually appealing and durable designs on promotional products. These methods play a crucial role in enhancing the overall aesthetic appeal and brand recognition of promotional items.

One commonly used technique is screen printing, which involves using a mesh screen to transfer ink onto the product to print your design. This method is known for its versatility and ability to produce vibrant colors.

Another popular option is pad printing, which utilizes a silicone pad to pick up ink from an etched plate and then transfer it onto the product. This technique allows for precise and detailed designs, making it ideal for logos or intricate artwork when the ink is applied.

Embroidery is another commonly used method, particularly for apparel items. It involves stitching a design directly onto the fabric using colored thread.

Heat transfer is also prevalent in the industry, where heat and pressure are applied to transfer ink using a special release paper from a printed image onto the product’s surface. This method is suitable for full-color designs and offers excellent durability.

Additionally, debossing and embossing techniques create raised or recessed impressions on materials such as leather or paper by applying pressure with engraved stamps or dies.

Digital printing has gained popularity due to its ability to print and process high quality images directly from digital files without requiring any plates or screens.

Choosing the right imprint method plays a significant role in creating visually appealing promotional products that effectively showcase a company’s logo or message. Screen printing, pad printing, embroidery, heat transfer, debossing/embossing techniques, and digital printing are among the most commonly used techniques that offer unique advantages depending on specific requirements such as design complexity and material type.

See our product suggestions:

Innovations and Future Trends

Innovations in imprint techniques and future trends are shaping the promotional product industry, paving the way for more advanced and creative methods of customization.

One notable innovation is the use of heat press technology. This technique involves applying heat and pressure to transfer a design onto a product, creating a durable and vibrant imprint. Heat press allows for intricate details and full-color designs to be transferred onto various materials such as apparel, bags, and accessories.

Another emerging trend in imprint methods is the printing process known as dye sublimation. This technique uses heat to transfer dye onto a material, resulting in a permanent and high-resolution image. Dye sublimation is ideal for producing full-color imprints with smooth gradients, making it popular for items like flags, banners, and custom apparel.

The demand for full-color imprints continues to grow in the promotional product industry. As a response to this trend, advancements have been made in digital printing technologies to achieve a full color to be imprinted on the products. These printers use inkjet or laser technology to apply ink directly onto the product surface, allowing for detailed designs with vibrant colors.

Additionally, sublimation printing has seen advancements that enable it to be used on new materials such as silicone. This allows for unique customization options to add logo onto products, like phone cases and wristbands.

Overall, these innovations demonstrate the ever-evolving nature of imprint techniques and printing uses in the promotional product industry. With advancements in heat press technology, dye sublimation processes, and digital printing methods, businesses can offer customers more options for creative and visually appealing customized products.

Conclusion

In conclusion, understanding the various imprint methods available is essential for businesses looking to add a design or logo to their promotional products.

Each method has its own advantages and disadvantages, and it is important to understand the most common factors like color options, durability, and cost should be considered when making a choice.

By selecting the most common types and suitable imprint methods, businesses can ensure that their promotional products effectively convey their desired message and meet their marketing goals.

With ongoing innovations and future trends in imprinting technology and printing machines, businesses can look forward to even more possibilities in creating impactful promotional items.